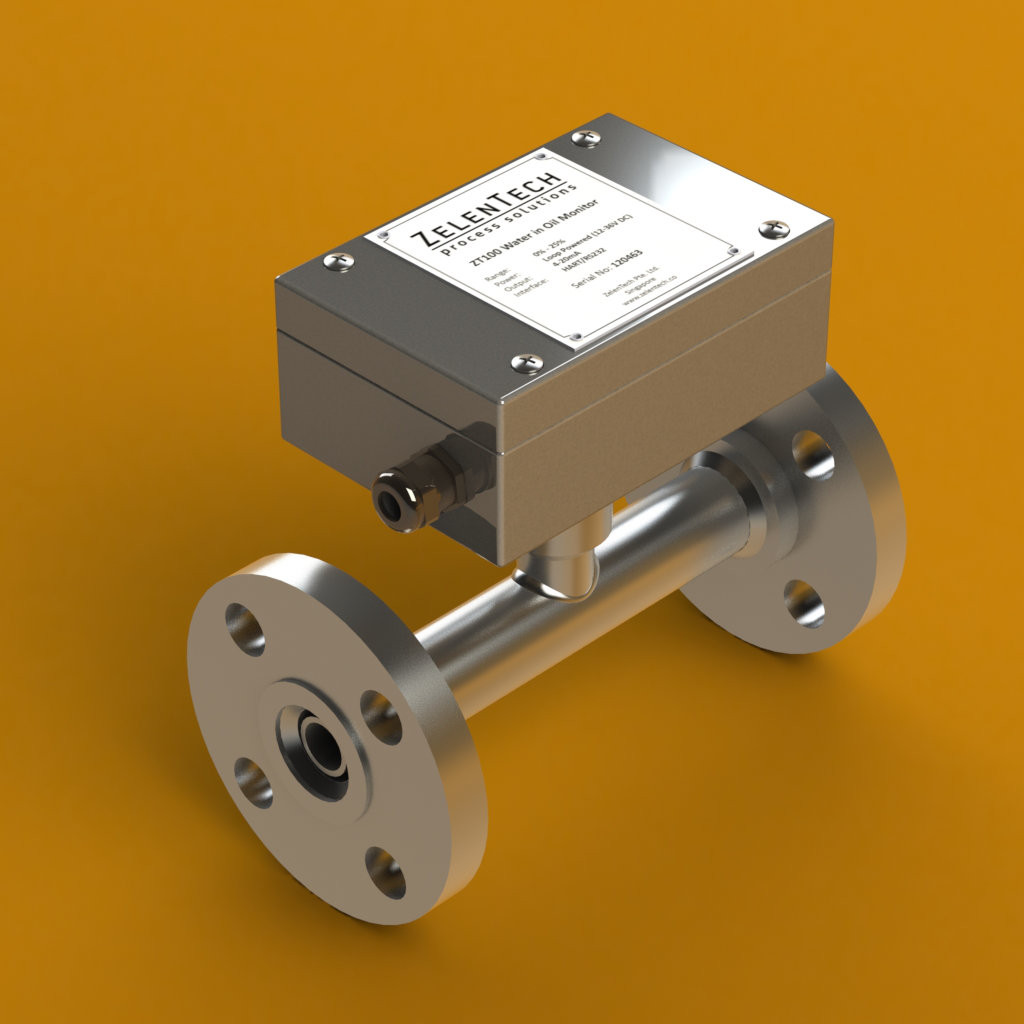

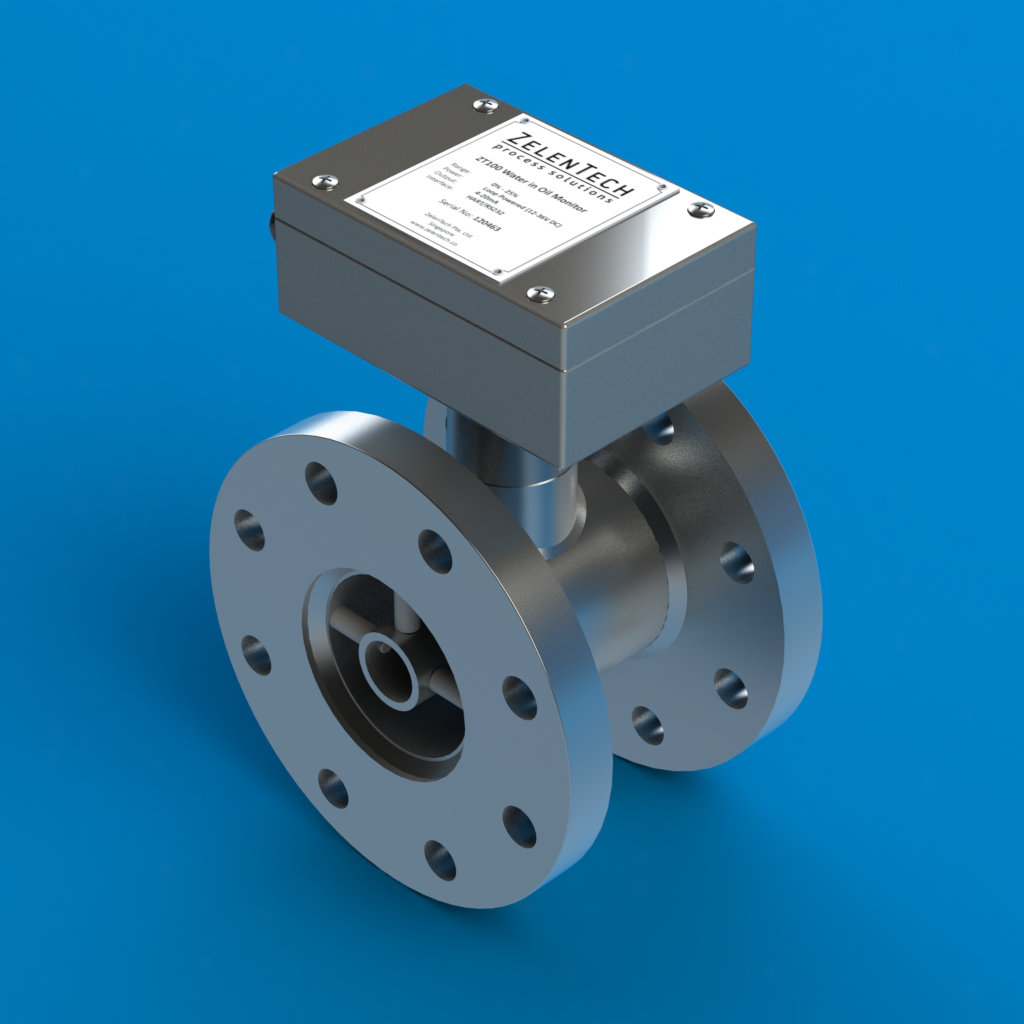

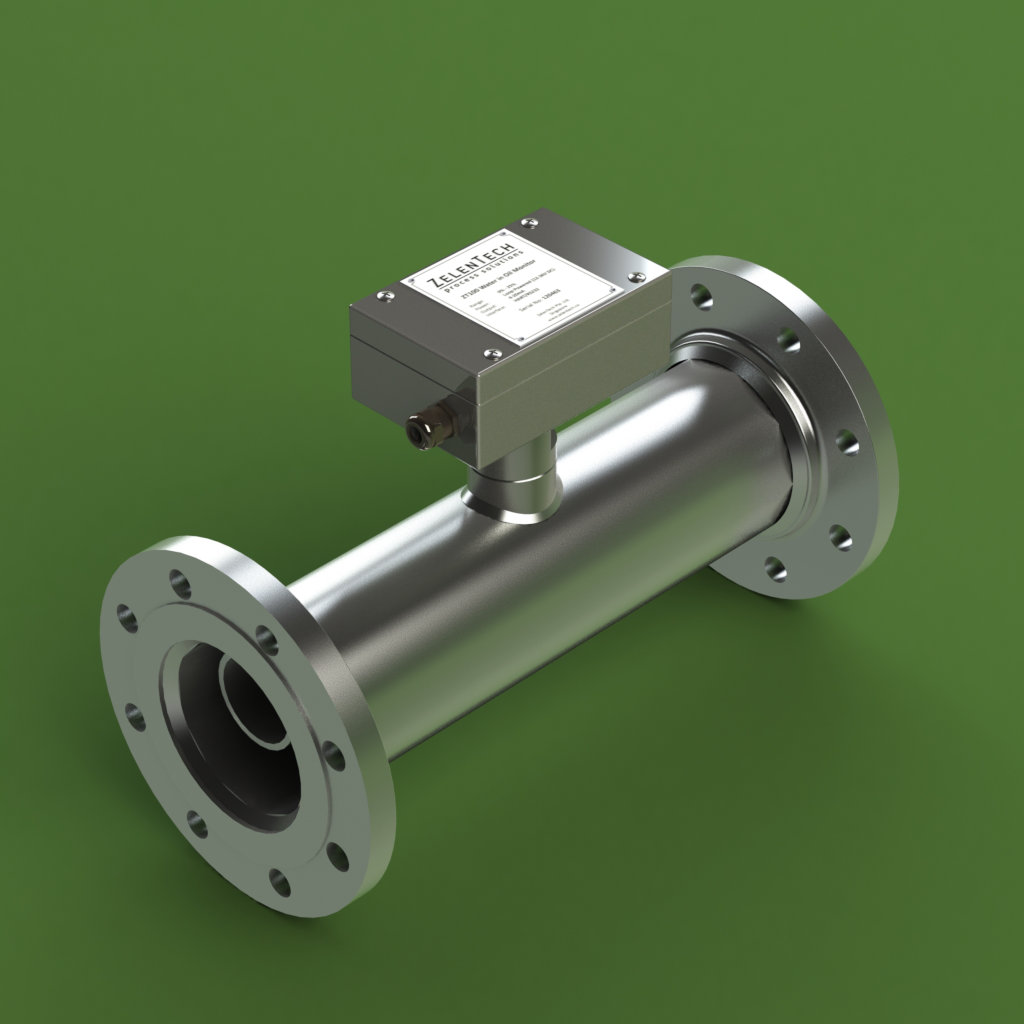

ZT-100 Water In Oil Monitors

The ZelenTech ZT-100 Water In Oil MonitowCrude Palm Oil (CPO) monitor offers real-time, fast response monitoring suitable for a variety oif applications.

The monitor can be used in applications such as lubrication oil, vegetable oils, gear box oil, hyrraulic oils and many more. The instrument is developed to accurately measure the content of water in ALL forms, free or dissolved. Awareness provides for preventive measures to take place. The advanced microprocessor enables fast, reliable and drift-free monitoring.

- Range: 0-25% Water Contamination